SYNERGY

Articulated Sprayer

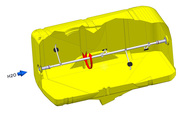

SYNERGY articulated pneumatic sprayer, based on the "Venturi tube" principle, allows for phytosanitary treatments with low-volume water mixtures; it performs phytosanitary treatments simultaneously on three rows.

The complete functional unit, including gearbox/fan and distribution sprayhead, is mounted on the tractor's three-point linkage.

The articulated joint, to which the trailer with the tank is attached, allows for extremely tight steering radiuses without ever disengaging the PTO. The drawbar can be adjusted in length, allowing the trailer wheels to overlap the tractor's. Maintenance is minimal, resulting in extremely low operating costs.

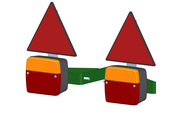

It can be approved for road circulation at full load.

The complete functional unit, including gearbox/fan and distribution sprayhead, is mounted on the tractor's three-point linkage.

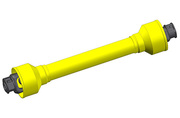

The articulated joint, to which the trailer with the tank is attached, allows for extremely tight steering radiuses without ever disengaging the PTO. The drawbar can be adjusted in length, allowing the trailer wheels to overlap the tractor's. Maintenance is minimal, resulting in extremely low operating costs.

It can be approved for road circulation at full load.

Specifications - Equipment ONLY FOR EC REGULATION

- Main polyethylene tank (800, 1000, 1500, and 2000 liters) with fully emptying and graduated level indicators.

- Polyethylene rinsing-washing tank positioned under the main tank (optimizes machine stability).

- 30-liter polyethylene hand-washing tank.

- Powder hydro-mixer integrated into the cup filter of the main filling access.

- Double agitation hydraulic and pneumatic (always homogeneous mixture).

- Maintenance-free CIMA centrifugal pump (without diaphragms and valves) made of corrosion-resistant material.

- Additional CIMA centrifugal agitation pump (without diaphragms and valves) made of corrosion-resistant material, supplied as standard on the 1500 and 2000 liter tank models.

- Electric pressure regulator and glycerine-filled pressure gauge, Ø 100 mm, scale 0-6 atm.

- Spraying with two on/off solenoid valves (one for the right and one for the left) with electrical control from the driver's seat. Spraying on the outside vegetation face could be cut off via two manual valves (one for the right and one for the left).

- Rotating disc flow regulators with 15 calibrated holes (which replaces pads), total spraying rate from 500 to 5,000 liters/h (depending on the operating parameters of a working speed between 6 and 8 m/s and a row width of 3 m, treatment dosis adjustable from approximately 100 l/ha to approximately 1,000 l/ha).

- High-pressure centrifugal fan with shut-off and polyethylene carter.

- Poly-V belt drive to the fan (no clutches required) with automatic belt tensioner

- Freewheel on the PTO

- Articulated steel frame, electrostatic polyester powder coating

- Wheel hubs with adjustable track and heigh

- Adjustable length trailer drawbar.

BOOM HANDLING AND STRUCTURAL CHARACTERISTICS

- The arms open independently, via hydraulic pistons connected directly to the tractor's oil connections. The system is telescopic and equipped with an adjustable mechanical stop, allowing precise setting of the opening based on the row width.

- The distribution sprayhead is equipped with a hydraulic piston for vertical movement, connected directly to the tractor's oil connections, which allows adjustment of the working height.

- Working field: Row width adjustment ranges from 2m to 3m in 0.1m increments – height adjustment for rows between 1.7m and 2.4m.

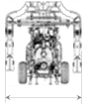

- Transport position: The telescopic arms are fully retracted and rotated towards the tractor cab, allowing for a transverse overall width of less than 2.5m.

- The arms are tubular in structure, ensuring high structural strength and lightweight construction.

- corrosion resistance is guaranteed with a modern two-coat powder coating process (primer + final coating)

SPRAYING

- SYNERGY allows simultaneous spraying on three rows, acting on six distribution sections (each section is dedicated to a single side of the row).

- Standard functioning: The pressure in the distribution circuit is regulated via an electric valve. Distribution can be activated or deactivated individually for the right or left side of the machine using dedicated electric valves.

The electric valves, both for pressure regulation and for managing the right and left distribution sections, are controlled via a dedicated button panel located inside the tractor cab.

It is also possible to exclude distribution on the outermost sides by operating two manual valves, one for the right and one for the left side. - Optional functioning: The pressure in the distribution circuit is regulated via the optional EPA (Delivery Proportional to Advance) control unit. Distribution can be activated or deactivated individually for the right or left side of the machine using dedicated electric valves, manually controlled by the same EPA control unit. It is also possible to exclude distribution on the most external sides by acting on two manual valves, one for the right side and one for the left side. Using a special optional kit, these manual valves can be replaced with two electric valves, also manually controlled by the EPA control unit. The EPA control unit can integrate the EASY FARM and EASY FARM VRT functional packages or the "agriculture 4.0" system.

Technical information

| SYNERGY 55 S | SYNERGY 55 E | |

|---|---|---|

| Tractor | Required power 58 kW - 80 CV | Required power 66 kW - 90 CV |

| Sprayer | Absorbed power 32 kW - 43 CV | Absorbed power 37 kW - 50 CV |

| Fan | Steel closed radial fan D.550 mm 3700 giri/min air delivery: 10800 m³/h air speed: 80 m/s |

Steel closed radial fan D.550 mm 3900 giri/min. air delivery:11500 m³/h air speed: 85 m/s |

| Pump | Centrifugal spray and agitation CD 32 pump - 4250 rpm. max delivery 140 l/min. - max pressure 4,5 kg/cm2 |

Centrifugal spray and agitation CIMA CD 32 pump - 4250 rpm max delivery 140 l/min. - max pressure 4,5 kg/cm2 |

| SYNERGY 55 | ||||||

|---|---|---|---|---|---|---|

| lt.800 | lt.1000 | lt.1000 "narrow" | lt.1500 | lt.2000 | ||

|

Min/max length with arms closed (transport/storage position) |

490/510 cm | 500/520 cm | 490/510 cm | 560/580 cm | 560/580 cm |

|

Min/max length from three-point linkage |

cm 343/363 | cm 353/373 | cm 343/363 | cm 413/433 | cm 413/433 |

|

Maximum width with arms open | cm 735 | cm 735 | cm 735 | cm 735 | cm 735 |

|

Width in transport position | cm 245 | cm 245 | cm 245 | cm 245 | cm 245 |

|

Height Min/Max |

cm 290/365 | cm 290/365 | cm 290/365 | cm 290/365 | cm 290/365 |

|

Empty weight (*) | kg 1175 | kg 1210 | kg 1190 | kg 1360 | kg 1390 |

|

standard wheel | 7.00 - 12 | 10/80 - 12 | 10/80 - 12 | 10/75 - 15.3 | 10/75 - 15.3 |

| optional wheel | 10/80 - 12 | 10/75 - 15.3 | 10/75 - 15.3 | 13.0/55 - 16 | 13.0/55 - 16 | |

| optional wheel | 26 x 12 - 12 | 13.0/55 - 16 | 13.0/55 - 16 | 11.5/80 - 15.3 | 11.5/80 - 15.3 | |

(*) vehicles not approved for road use